Many laboratory processes are extremely temperature-sensitive. Even small fluctuations in process or storage temperatures can invalidate results or destroy sensitive samples. To contend with these challenges, laboratories must implement reliable monitoring and alarm systems that alert staff when temperatures fall outside acceptable ranges.

Laboratory temperature monitoring systems capture temperature data at short time intervals to verify that they are within range. Abnormal readings trigger an alarm mode until staff have identified and corrected the problem. In doing so, they maintain efficient processing, protect sensitive samples, and keep facilities compliant with strict regulatory standards.

At Digital Instruments, we design and manufacture high-performance sensing and monitoring equipment needed in laboratory environments. Our laboratory monitoring systems are completely customizable, ensuring safe, efficient, and traceable processing in any lab setting.

What are Lab Temperature Monitoring Systems?

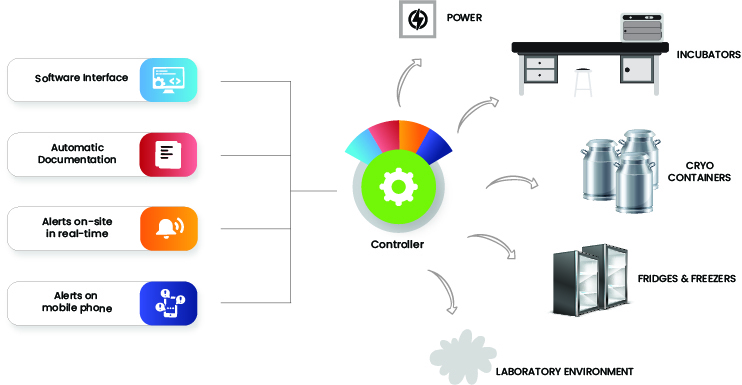

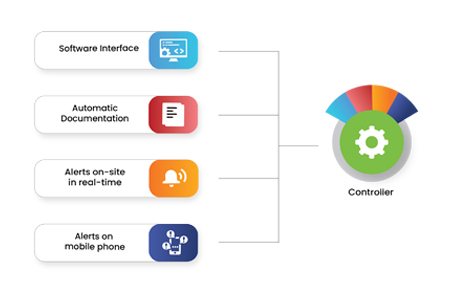

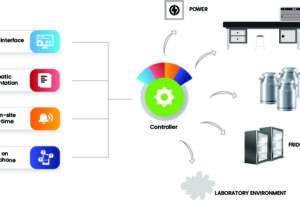

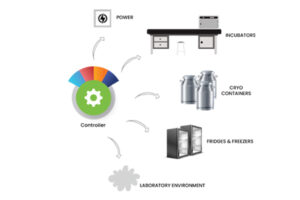

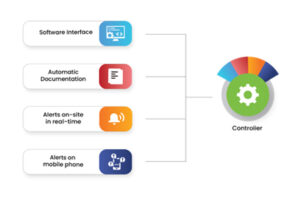

Lab temperature monitoring systems combine precise, around-the-clock temperature sensing with cloud-based data logging and alarm capabilities. Together, these components create a comprehensive temperature monitoring system that keeps laboratories running smoothly.

Lab temperature monitoring systems capture critical data from equipment like liquid nitrogen tanks, freezers, and incubators. They operate 24/7 with no need for hands-on supervision, making process monitoring effortless. Every few minutes, a sensor measures and logs the temperature within the system. If a reading exceeds the set temperature range, the system alerts staff to the anomaly so they can quickly restore the system to its proper parameters. These alerts can be sent to pre-selected staff members via text message, phone call, or email, ensuring a timely response at any time of day.

Lab temperature monitoring systems are critical in research applications across biomedicine and pharmaceuticals because they maintain efficiency and protect expensive or irreplaceable samples from damage. They also simplify record-keeping by automatically logging critical data in a secure, cloud-based archive. From these records, staff can generate custom reports detailing all temperature readings, alarm events, and staff responses. These records enable accurate traceability and quality assurance efforts.

The Benefits of Laboratory Temperature Monitoring Systems

Laboratory temperature monitoring systems play an essential role in many laboratory applications. Whether it’s for maintaining or processing sensitive samples, these systems ensure that the temperature remains at an acceptable setpoint.

Additional advantages of these systems include:

- Improved Facility Safety: In many research and healthcare settings, temperature fluctuations can have serious consequences. Excess heat in storage facilities, for instance, can destroy sensitive and potentially irreplaceable samples. Excess heat in healthcare and research settings can also present safety hazards to animal subjects, patients, and workers. Temperature monitoring equipment protects against these outcomes by alerting staff to potentially hazardous temperature swings.

- Continuous, Real-Time Data Recording: By recording measurements every few minutes, laboratory monitoring systems give the most comprehensive picture of temperature fluctuations possible. Custom report formats allow staff to make the most of this wealth of data, with access to both high-level overviews and to-the-minute data points. Aside from aiding in reporting and compliance, these data also help staff spot trends and identify problems before they escalate. This helps keep equipment functioning at optimal levels long term.

- Early Warning of Malfunctions: Real-time monitoring ensures that you always know what is happening in your facility. Whether it’s a small temperature fluctuation or a major power outage, temperature monitoring systems immediately alert staff to take corrective action. Aggregated data also helps to highlight slow changes in equipment performance. These longer-term trends can indicate that equipment is failing before it’s too late, preventing costly downtime. Custom alerts can even bring these trends, as well as scheduled maintenance requirements, to your staff’s attention.

- Maximal Productivity: Automated monitoring helps staff at all levels become more efficient. Technicians are freed from constant in-person monitoring, allowing them to do more skill-based work. Additionally, managers and quality assurance staff have easier access to critical data, simplifying their workflows for data analysis and reporting.

- Facilitating Compliance: Strict industry and quality assurance standards require facilities to maintain comprehensive records regarding processing parameters. Temperature monitoring systems automatically collect, record, and organize these data so that they are immediately available for reporting. Cloud integration further ensures that the data are immediately accessible and securely backed up.

- Easy Data Access: Unlike physical logs or simple spreadsheets, cloud-based logs are accessible from any computer, smartphone, or tablet, anywhere in the world. All employees who may need access to temperature data can quickly and easily find the most recent records. This feature is especially valuable when there is an alarm, as all staff can immediately view the situation and the recordings that preceded the problem. It is also useful for routine tasks, such as sharing performance data with maintenance staff.

Temperature monitoring systems are extremely powerful and flexible systems that can be adapted to meet your facility’s precise needs. With a single investment, they allow laboratories to improve efficiency, simplify workflows, and protect expensive materials.

Industries That Use Lab Temperature Monitoring Systems

Lab temperature monitoring systems can benefit any industry that stores temperature-sensitive samples and chemicals, or that performs temperature-sensitive reactions. They are equally useful in industrial R&D labs as well as in healthcare centers. Facilities that are especially reliant on laboratory temperature monitoring include:

- IVF centers (including andrology labs and embryology labs)

- Hospitals and treatment centers

- Pharmaceutical research and manufacturing

- Industrial and academic research labs

- Blood and tissue banks

- Biobanks and cryobanks

- Food processing

More specifically, monitoring equipment is often fitted to the following pieces of equipment:

- Refrigerators, freezers, coolers, and cold rooms

- Liquid nitrogen tanks

- Blanket warmers

- Cleanrooms

- Calibration equipment

- Incubators

- Stability testing chambers

- Dryers

- Air compressors

- Animal housing

In all of these settings, temperature monitoring enhances safety and efficiency while making it easier for workers to do their jobs.

Laboratory Temperature Monitoring Systems from Digitial Instruments

At Digital Instruments, we understand the strict regulations that constrain pharmaceutical and biomedical processes. Our laboratory temperature monitoring systems are designed to maintain optimal operating conditions, whatever your specific requirements.

All of our monitoring systems feature accurate readings with integrated remote monitoring capabilities. Each system combines high-performance sensors to collect data, multiple I/O lines to integrate essential control functions, and reliable wireless nodes to enable reporting and logging. We also allow clients to customize their system’s size, shape, configuration, and components to suit existing equipment and application requirements.

Contact Our Team Today

Our teams are experts in both the design and engineering of accurate monitoring systems. To learn how our turnkey laboratory monitoring solutions can benefit your facility, request a quote today.